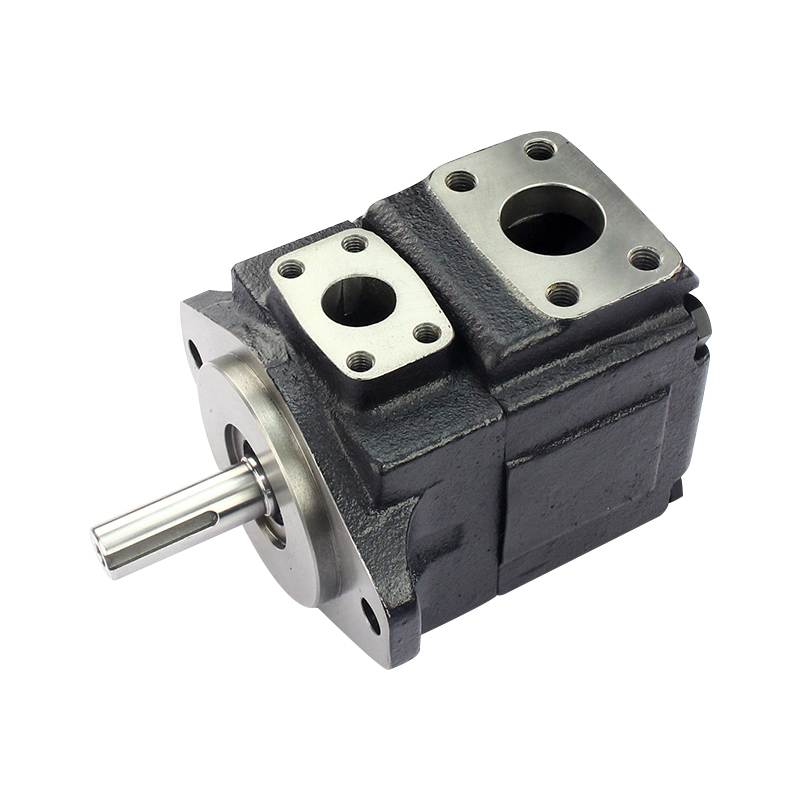

Hydraulic components play a crucial role in the injection molding machinery industry, being widely used for optimizing the functions and performance of various injection molding machines.

1. Application Areas

Clamping System: Hydraulic components are used in the clamping system to ensure the stability and safety of the molds during the injection process, preventing any displacement of the molds during injection.

Injection System: Hydraulic-driven injection devices can inject molten plastic into molds under high pressure, ensuring the precision and uniformity of plastic forming.

Holding Pressure System: The hydraulic system maintains holding pressure within the mold, preventing shrinkage of the plastic during cooling, ensuring the accuracy of the finished product dimensions.

Ejector System: Hydraulic ejector devices are used to remove the finished product from the mold, ensuring the integrity of the product and enhancing production efficiency.

2. Advantages

High Efficiency: Hydraulic systems can quickly generate high pressure, suitable for rapid injection and forming, significantly enhancing production efficiency.

Precise Control: Hydraulic components allow for precise adjustments of injection speed, pressure, and holding time, ensuring stability and consistency in the injection molding process.

Good Load Capacity: Hydraulic systems can withstand high loads, making them suitable for various specifications of injection machines.

Strong Adaptability: Hydraulic systems can operate stably under different production conditions, accommodating a variety of plastic materials for injection molding.

3. Features

Modular Design: Hydraulic components are typically designed in a modular format, facilitating maintenance and replacement, and reducing repair costs.

Durability: Hydraulic components are usually made from high-strength materials, offering good wear resistance and corrosion resistance, suitable for long-term operational demands.

Multifunctionality: The hydraulic system can be flexibly configured to meet the diverse functional needs of different agricultural machinery.

Safety: The hydraulic system is equipped with multiple safety devices to prevent overload and malfunction, improving operational safety.

summary

Hydraulic components are widely used in the agricultural machinery industry due to their high efficiency, precise control, and good load capacity. Its modular design and durability make maintenance more convenient, making it an indispensable and important component of modern agricultural machinery, and contributing to the modernization and efficiency of agricultural production.

English

English русский

русский Español

Español عربى

عربى