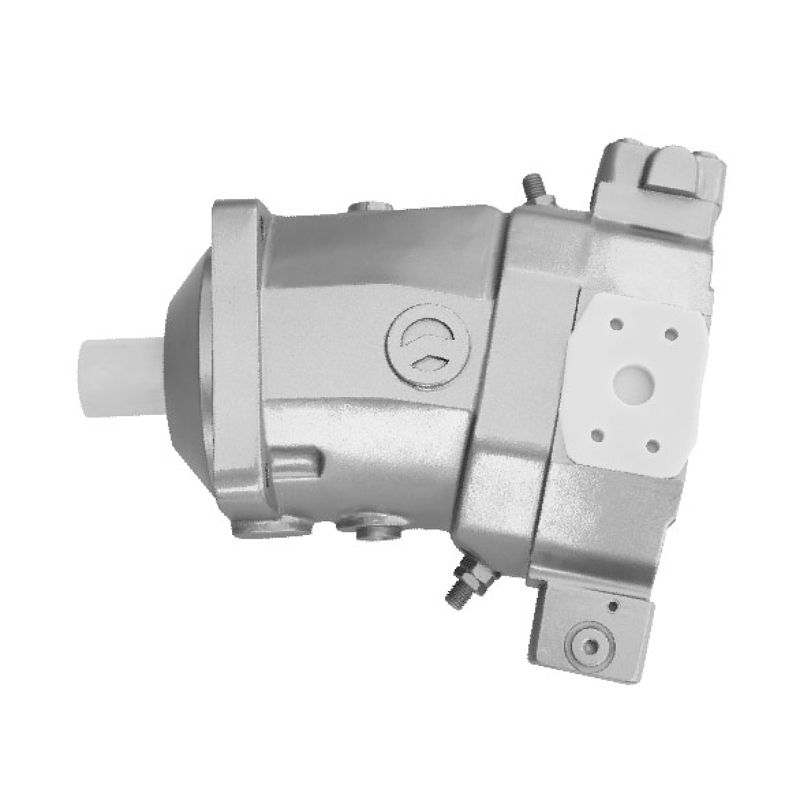

Piston motors convert the reciprocating linear motion of a piston into rotational motion, usually through a series of key components and mechanisms. Here is a detailed explanation of this process:

1. Reciprocating motion of the piston

The heart of a piston motor is the piston, which is located in a sealed cylinder. The piston reciprocates in the cylinder through external power (usually from the expansion of gas or compression of gas in the combustion chamber). The movement of the piston is driven by the following factors:

Gas expansion: In an internal combustion engine (such as a gasoline engine or a diesel engine), the mixture of fuel and air is ignited in the cylinder, and the gas expands, pushing the piston up and down or forward and backward along the inner wall of the cylinder.

Gas compression: In a compressor, air is compressed, generating high pressure and temperature, which pushes the piston to move toward one end of the cylinder.

2. The conversion mechanism of the connecting rod and the crankshaft

The linear reciprocating motion of the piston is converted into rotational motion through a component called a **connecting rod**. One end of the connecting rod is connected to the piston and the other end is connected to the crankshaft. The crankshaft is a key component in a piston motor that converts the linear motion of the piston into rotational motion.

Connection between connecting rod and piston: The piston is connected to the connecting rod through a piston pin, and the other end of the connecting rod is connected to the crankshaft through a hole at the end of the connecting rod. The up and down reciprocating motion of the piston (along the cylinder direction) is transmitted to the crankshaft by the connecting rod.

Rotation of the crankshaft: As the piston moves up and down, the connecting rod converts the linear motion of the piston into the rotational motion of the crankshaft. The rotational motion of the crankshaft can drive mechanical equipment or generate power output.

3. Operation and power output of the crankshaft

The rotation of the crankshaft is achieved by the superposition of multiple piston movements. In an engine, there are usually multiple cylinders, each of which consists of a piston and a connecting rod. These cylinders work alternately, that is, each piston performs the process of compression, ignition, work and exhaust at different times. Through the alternating motion of the piston, the crankshaft is continuously pushed to form a smooth rotation output.

Four-stroke engine: In a common four-stroke engine, each piston goes through four stages: intake, compression, work, and exhaust. Each stage pushes the piston to move up and down along the cylinder, and the connecting rod and crankshaft system convert these movements into the rotation of the crankshaft.

Two-stroke engine: In a two-stroke engine, each up and down movement of the piston corresponds to a power cycle, so its rotation frequency is higher. Although the working cycle of a two-stroke engine is different from that of a four-stroke engine, the linear motion of the piston is still converted into rotational motion through the connecting rod and crankshaft.

4. Interaction of key components

Flywheel: The flywheel is usually connected to the other end of the crankshaft to balance the vibration and fluctuations when the engine is running. The rotation of the flywheel stores some rotational energy and helps to output power smoothly, especially when the piston movement is not completely smooth, the flywheel helps to maintain the continuity of rotation.

Camshaft: The camshaft is used to control the opening and closing of the valve. The order of the intake and exhaust process is very important. It is connected to the crankshaft through gears or chains to synchronize the reciprocating motion of the piston and the action of the valve.

With multiple cylinders working together, piston motors are able to smoothly produce continuous rotational power, which is also the working principle used in most internal combustion engines (such as car engines) and many industrial machines.

English

English русский

русский Español

Español عربى

عربى