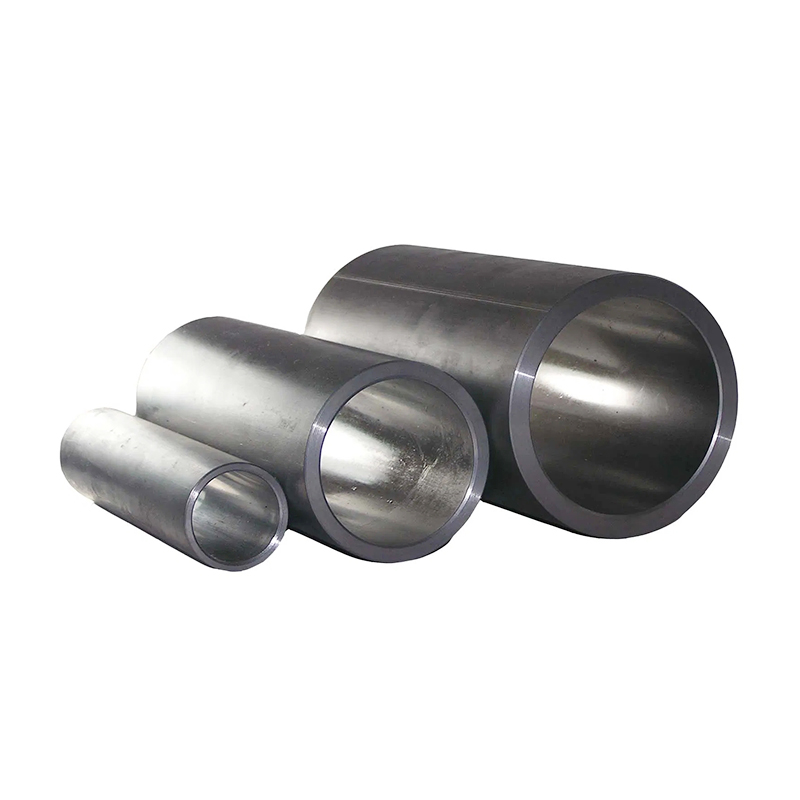

Cold-drawn cylinder tubes are cold-drawn to have a high precision inner diameter and surface smoothness. This is very important for the sealing performance and fluid power transmission of the cylinder. The cold drawing process can provide an excellent surface finish, reduce friction and wear, and increase the service life of the cylinder. Cold-drawn cylinder tubes usually use high-strength steel, such as carbon steel or alloy steel, which has good mechanical properties after cold drawing and can withstand high pressure and high load. High-quality cold-drawn tubes have good fatigue resistance and are suitable for high-frequency reciprocating motion environments.

English

English русский

русский Español

Español عربى

عربى